UNSERE MASCHINEN

Unsere Maschinen bieten fortschrittliche Lösungen für die Fleischverarbeitung. Unser Katalog umfasst ein komplettes Sortiment an Geräten, darunter Industrie Gefrierfleischwölfe, Fleischwölfe, Mischanlagen und Logistiksysteme, die für Effizienz und Qualität im Produktionsprozess ausgelegt sind. Mit Fokus auf die spezifischen Bedürfnisse unserer Kunden bieten wir maßgeschneiderte Maschinen, die als Produktionslinie die Lebensmittelproduktion optimieren.

TIPOLOGIA

Mischwolf TM-TMR-TMV

Automatenwölfe TA6 – TA

Feinwolf TAM

Winkel Wolf TMV180V Vakuum

Dreikopf Feinwolf 3T

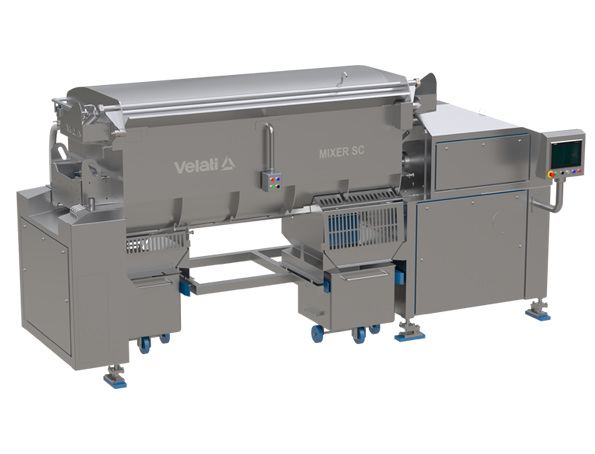

Mischer mit Kastenentladung SC

Mischer mit Frontentleerung SF

Kippmischer VR

VORMISCHER

Durchlauf Vorschneider FINIMONDO F1-F3-F4

Gefrierfleischwölfe THOR 250

Gefrierfleischwölfe THOR 300/400

Rotations Flaker SP

CUBE Würfelschneider

FETTWÜRFEL WASCHMASCHINE

DOSIERSCHNECKEN

SALZSTDOSIERER GEWÜRTSDOSIERER

KOLBENFÜLLMASCHINE SIXPI

TRANSPORTBÄNDER und -SCHNECKEN

SALAMI Schleuder