OUR MACHINES

Our machines offer advanced solutions for meat processing. Our catalogue includes a complete range of equipment, including industrial meat grinders, mixing plants and cooking systems, designed to ensure efficiency and quality in the production process. With a focus on the specific needs of our customers, we provide customized machinery that optimizes food production.

TYPES

Grinders TM – TMR – TMV

Grinders TA6 – TA

Grinder Refiner TAM

Angular Grinder TMV180V

Triple Head Grinder 3T

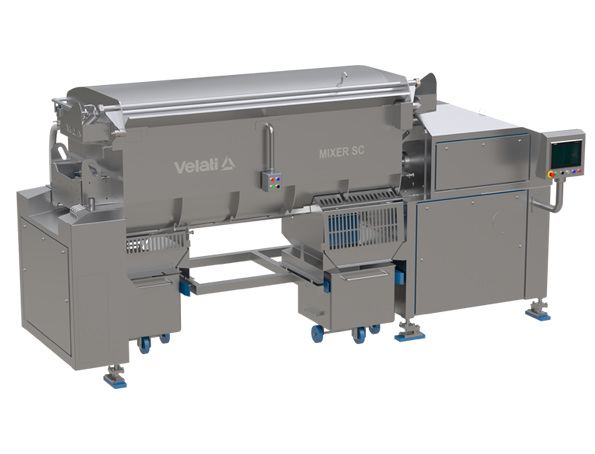

Mixer with Unloading by Hatches SC

Frontal Unloading Mixer SF

Tilting Tank Mixer VR

Blenders

Continuous Meat Cutter FINIMONDO F1-F3-F4

Grinder Breakers THOR 220/250

Grinder Breakers THOR 300/400

Flacker SP

DICING Machine

Fat Heating and WASHING Machine

Dosing Worm

SALT Device – SPICE Device

SIXPI Filler

CONVEYOR Belts and WORMS

SPREADING Machine