LE NOSTRE MACCHINE

Le nostre macchine offrono soluzioni avanzate per la lavorazione della carne. Il nostro catalogo include una gamma completa di attrezzature, tra cui tritacarne industriali, impianti di miscelazione e sistemi di cottura, progettati per garantire efficienza e qualità nel processo produttivo. Con un’attenzione alle esigenze specifiche dei clienti, forniamo macchinari su misura che ottimizzano la produzione alimentare.

TIPOLOGIA

Tritacarne TM6

Tritacarne TM – TMR – TMV

Tritacarne TA6 – TA

Tritacarne Raffinatore TAM

Tritacarne Angolare TMV180V

Tritacarne Tripla Testa 3T

Impastatrice a scarico a casetti SC

Impastatrici a Scarico Frontale SF

Impastatrice a vasca ribaltabile VR

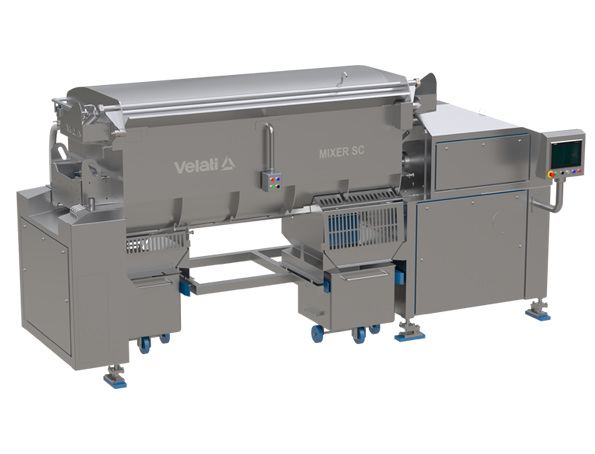

Miscelatore

Tagliacarne continuo FINIMONDO F1-F3-F4

Tritacarne Frantumatore THOR 220-250

Tritacarne Frantumatore Thor 300/400

Sgrossatrice SP

Cubettatrice CUB

Scalda Lava Lardello

Coclea Dosatrice

Dosasale Dosaspezie

Insaccatrice Sixpi

Nastri e Coclee